Materials That Soar: Inside Aerospace Composite Technology

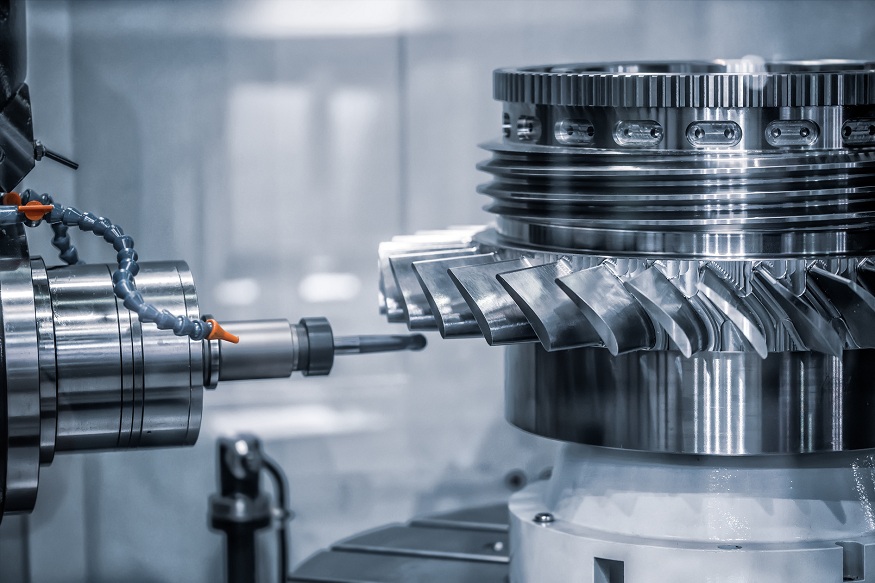

Metalworking CNC milling machine. Cutting metal modern processing technology. Small depth of field. Warning - authentic shooting in challenging conditions. A little bit grain and maybe blurred.

Every commercial plane that flies over American skies today harbors a secret. Beneath the paint resides a material revolution that has subtly changed aviation in the last thirty years. These are not the aluminum panels that constructed the aviation sector. They’re much more advanced; composite materials that merge various substances to form something stronger, lighter, and more effective than any individual material by itself.

What Makes Composites Special

Consider a composite as similar to a chocolate chip cookie. The dough gives structure. The chips contribute unique qualities. Combined, they are better. The people at Aerodine Composites say that in aerospace composites, carbon fibers act like the chocolate chips, providing incredible strength. Plastic or resin acts as the dough. It binds and shapes the final product.

Magic occurs at the microscopic level. Carbon fibers are incredibly strong despite their size. When many fibers are arranged in a particular way and bound with resin, the result is sheets that are both tougher than steel and less heavy than aluminum. Engineers adjust fiber orientation for specific stresses. Much like a tailor fitting a suit.

This personalization runs deep. Certain areas require greater adaptability. Some demand the highest level of stiffness. By altering the fiber layout and resin composition, producers develop materials that are ideally tailored for every aircraft part. The wing may utilize one composite formulation, whereas the fuselage employs a different one.

The Advantages That Changed Everything

Weight reduction propels the composite revolution. Composite aircraft are about 20% lighter than all-metal ones. Fuel consumption decreases with less weight. Less fuel use means lower costs and emissions. This difference saves a lot of jet fuel on long flights.

Composites do not corrode. Metal planes continually face challenges from rust and wear. Salty air corrodes aluminum. Pressure forms small fractures that extend as time passes. Composites withstand these issues. They do not rust. They cope with recurring stress more effectively. A plane constructed with composite materials requires reduced upkeep and has a longer lifespan.

The comfort of passengers also improves. Composite fuselages manage greater cabin pressure, creating a sensation for passengers like being at a lower altitude. The air indoors remains moister. Tourists reach their destinations feeling less fatigued and more hydrated. Windows may be bigger since composites manage structural loads differently compared to metal.

The Challenges Engineers Face

Flawless materials don’t exist. Composites come with their own challenges. Lightning strikes present specific risks. Metal planes transmit electricity safely along the aircraft’s body. Composites are poor electrical conductors, requiring engineers to incorporate special conductive layers for safety.

Detecting damage necessitates innovative methods. A noticeable dent appears in aluminum. Composite damage frequently remains concealed beneath the surface. Technicians require specific tools, like ultrasound scanners and thermal cameras, to identify issues. Teaching mechanics to handle these materials requires time and resources.

The intricacies of manufacturing exasperates production managers. Manufacturing composite components requires accurate temperature regulation, meticulous layer positioning, and extended curing durations. A single error in the process can jeopardize a whole component valued at hundreds of thousands of dollars.

Tomorrow’s Composite Aircraft

The upcoming generation guarantees even greater transformations. Researchers work with self-repairing composites that autonomously fix minor fractures. Some create composites that alter their shape based on flight conditions, enhancing performance instantly. Production rates will rise. Innovative methods enable composites to set in minutes instead of hours. Automated systems will create fiber patterns with flawless accuracy. Expenses will decrease as output increases.

Conclusion

Composite technology has already transformed aviation . Modern aircraft travel greater distances. They also consume less fuel and have longer lifespans because of these exceptional materials. The future of aviation isn’t solely focused on improved engines or advanced computers. It’s centered on the groundbreaking materials that unify everything.