Sealing Techniques for Reliable Hermetic Feedthroughs

Hermetic feedthroughs are critical components used to maintain electrical, optical, or fluid connections through airtight or vacuum-sealed barriers. Their performance and reliability depend largely on the sealing techniques used during manufacturing. Proper sealing ensures that sensitive equipment in aerospace, medical, industrial, and scientific applications remains protected from moisture, air, and contaminants. Understanding the different sealing techniques is essential for selecting the right feedthrough and ensuring long-term performance.

Importance of Sealing in Hermetic Feedthroughs

The primary purpose of a hermetic feedthrough is to maintain the integrity of a sealed environment while allowing connections to pass through. A poorly sealed feedthrough can lead to:

- Electrical failures due to moisture or contamination

- Loss of vacuum or pressurization in sensitive systems

- Reduced lifespan of critical components

- Safety hazards in high-voltage or high-pressure applications

Therefore, reliable sealing is critical for ensuring both the functionality and longevity of the system.

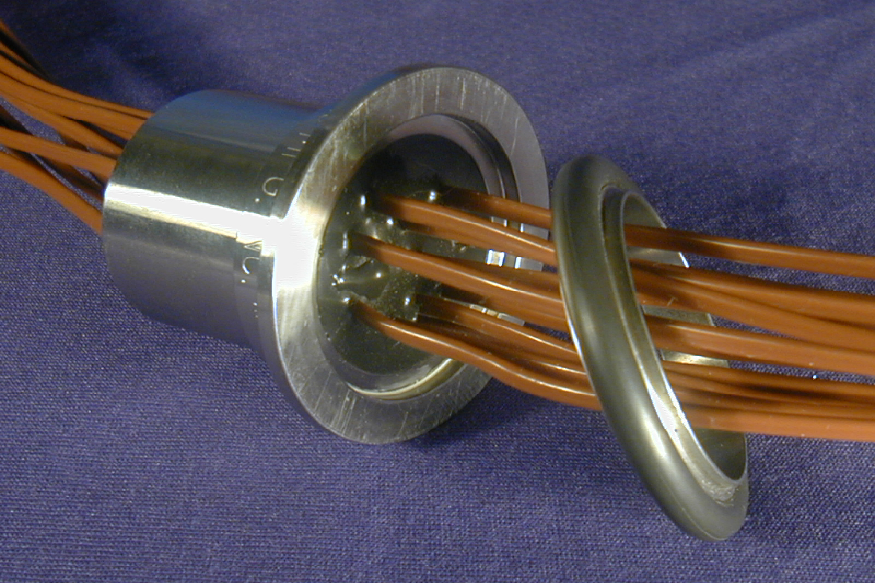

Glass-to-Metal Sealing

Glass-to-metal sealing is one of the most common and reliable techniques used in hermetic feedthroughs. In this method, metal pins are embedded in a glass insulator, which is then fused to a metal housing.

Advantages:

- Provides excellent electrical insulation and dielectric strength

- Maintains a strong vacuum or airtight seal

- Handles thermal cycling and mechanical stress effectively

Applications:

- High-voltage systems

- Vacuum chambers and scientific instruments

- Semiconductor processing equipment

Glass-to-metal sealing is particularly effective when precision, vacuum integrity, and electrical insulation are essential.

Ceramic-to-Metal Sealing

Ceramic-to-metal sealing uses a ceramic insulator, often alumina, fused or brazed to a metal housing. This technique is favored for high-temperature and high-pressure applications because ceramics provide superior mechanical strength and thermal stability.

Advantages:

- Can withstand extreme temperatures

- Resistant to mechanical shock and vibration

- High dielectric strength ensures electrical insulation

Applications:

- Aerospace electronics

- Industrial furnaces and high-pressure systems

- Medical imaging and implantable devices

Ceramic-to-metal seals are ideal when both mechanical durability and hermeticity are required.

Welding Techniques

Metal welding is often used for feedthroughs that require maximum mechanical strength and environmental resistance. Techniques such as laser welding or electron beam welding can create precise, airtight seals between metal components.

Advantages:

- Extremely strong and durable

- Ideal for high-pressure and high-vibration environments

- Compatible with complex geometries

Applications:

- Aerospace and defense systems

- High-pressure industrial equipment

- Harsh chemical or marine environments

Welding provides a reliable seal for applications where glass or ceramic might be vulnerable to mechanical stress.

Brazing Techniques

Brazing involves joining metals using a filler material with a lower melting point than the main components. This technique is often used to bond ceramics or glass to metal in hermetic feedthroughs.

Advantages:

- Creates strong, leak-proof joints

- Compatible with complex shapes and multi-pin designs

- Handles moderate thermal and mechanical stress

Applications:

- Multi-pin industrial feedthroughs

- Medical devices requiring sterilizable seals

- Vacuum and cryogenic systems

Brazing provides flexibility in design while maintaining a reliable hermetic seal.

Advanced Coatings and Sealants

In some modern applications, advanced coatings or sealants are used to enhance the sealing performance of feedthroughs. These coatings can provide additional protection against corrosion, chemical exposure, or micro-leaks in challenging environments.

Advantages:

- Increases lifespan of feedthroughs in harsh conditions

- Prevents corrosion and degradation

- Improves vacuum and airtight integrity

Applications:

- Chemical processing equipment

- High-humidity or marine environments

- Long-term aerospace and satellite systems

Advanced sealants and coatings complement traditional sealing methods to ensure maximum reliability.

Factors to Consider for Reliable Sealing

When selecting a hermetic feedthrough, consider the following factors:

- Operating Environment: Temperature, pressure, chemical exposure, and vibration

- Signal Requirements: Electrical, optical, or fluid transmission

- Mechanical Stress: Ensure the seal can handle shock and thermal cycling

- Material Compatibility: Glass, ceramic, or metal should match housing materials to prevent leaks

- Longevity: Choose sealing techniques suited for long-term applications

Understanding these factors ensures the feedthrough remains functional and reliable throughout its operational life.

Conclusion

Reliable hermetic feedthroughs depend heavily on effective sealing techniques. Glass-to-metal and ceramic-to-metal seals provide excellent electrical insulation and environmental protection, while welding and brazing offer mechanical strength and durability. Advanced coatings and sealants further enhance performance in harsh conditions. By carefully considering the operating environment, materials, and application requirements, engineers can select hermetic feedthroughs with the right sealing method, ensuring optimal performance and longevity in aerospace, medical, industrial, and scientific applications.